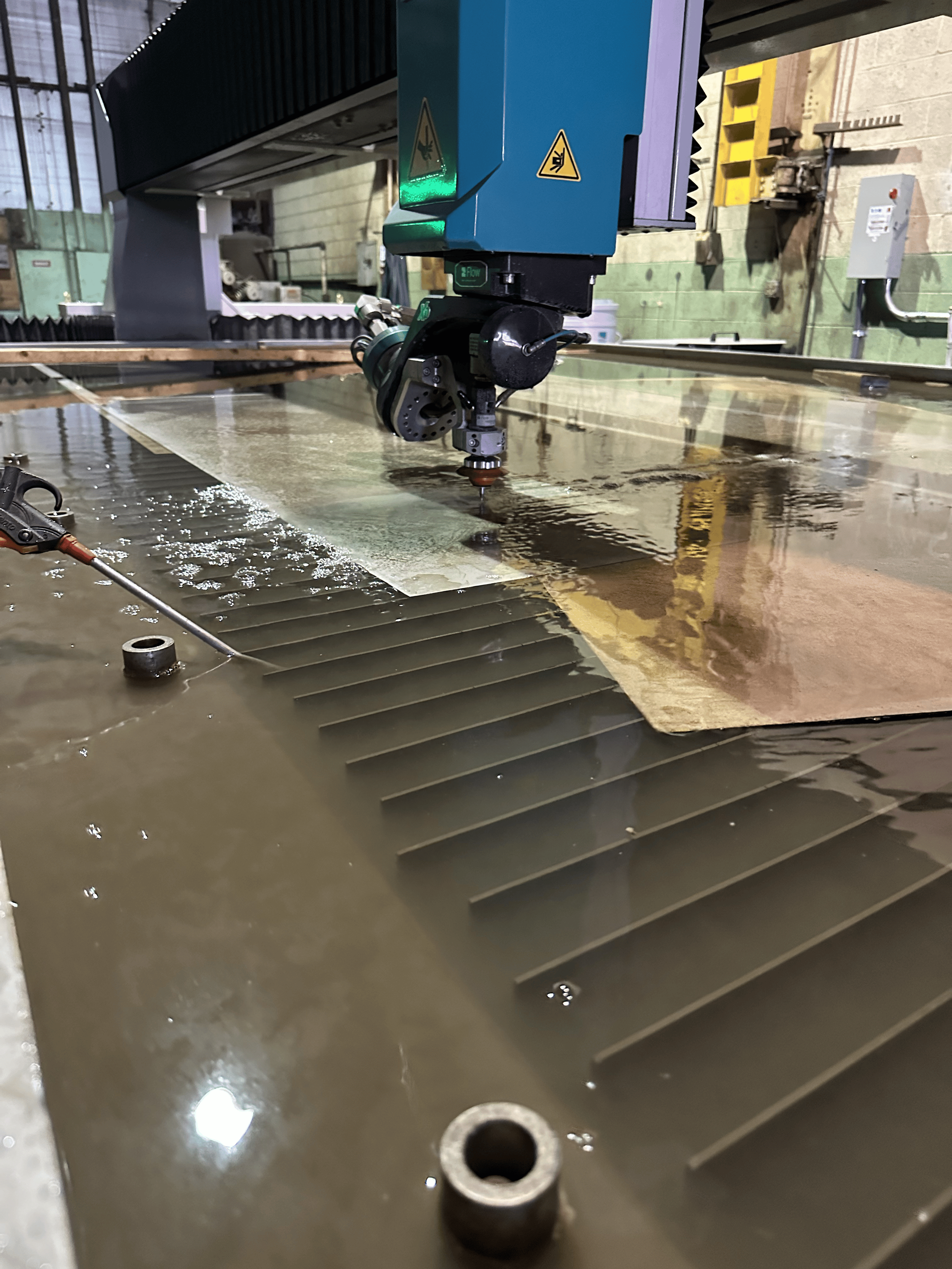

Waterjet Services

Our Promise

No matter how complex or advanced the part you need is our promise to you is that we will help you get the job done. In the metal industry there are quite a few projects that require specialty parts or one off pieces that have to be made to complete the project. As a company we dedicate our resources to solving those complications and get everything to working order. Whether you need specialty flanges, custom bevels, bracketry parts, or even a custom sheet to finish off the job, we love providing the answer. Listed below are the resources we offer to you to finish off any complications! Feel free to reach out to us and gather our professional thoughts.

What Opportunities We Share

-

Wild Precision

Our CNC Waterjet provides tight tolerances for any project you need! With a machine tolerance of ±.003 we can work with any project thrown are way.

-

Stellar Design

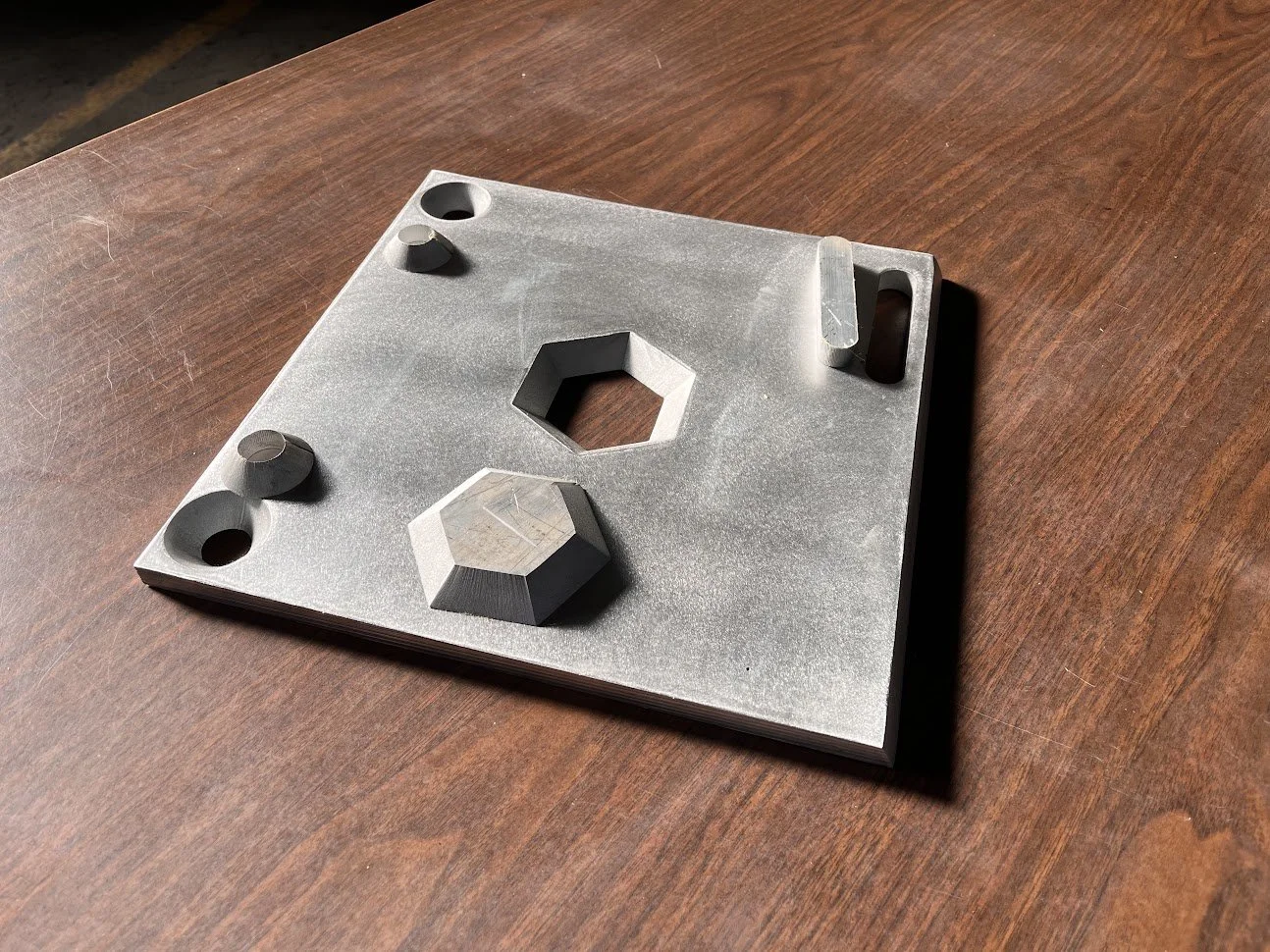

Our team provides a stellar design for your project. Whether it’s just a model for a potential job, or a finished part!

-

Multi-Axis Capabilities

Have you ever needed the perfect bevel for your project? We have provided that service for many on a wide variety of projects. This includes beveled flanges, test plates and more!

-

Thick Material Cutting

With our CNC processes, we are able to cut up to 10 inch material, and while that is certainly an extreme use of our equipment, it is possible. We have had great success cutting materials anywhere from 16 gauge steel to 6 inch exotic metals! Whether your project needs large precise parts to fit into an existing mechanical system or simple gusset/supporting features, our team has you covered!

-

Multi-Material Capabilities

One of our favorite functions of our CNC setup is the multi-material friendliness. For example, we have cut gasket material, plastics, polypropylene, stone, mirror glass, and much more! We have found that this helps a multitude projects in various different ways.

-

Etching

Another service that we provide on our CNC setup is etching. We have found it useful in many interesting ways such as a tool for fit up, marking important information, and making grids on fixture plates and tables. No matter the project, we can guarantee quality etching for your project!

More Specs for our Waterjet Setup

Table Work Area: 6’ x 13’

Cutting Tolerance: +/- .003”

Multi-Axis Cutting: up to 60 Degrees

Material Capabilities: Steel, Stainless Steel, Aluminum, Exotic Alloys, Plastics, Gasket Materials, Stones (Marble, Granite, Quartz), Glass, Rubber

Thickness Capabilities: Up to 10”

Molecular Impact: None, this is a cold-cutting process that keeps your material molecular structure untouched (such as hardened materials)

Model: Flow Mach 500 w/ XD Cutting Head

How Does This Help You?

Now you might be wondering how our services can help you? And to be frank, it depends on what projects you have going on. With our setup, we do a lot of research and development, make custom flanges, large support pieces (such as gussets), pre-fabbed plates (such as a pintle plate). If you have the design or an idea, we make it into reality. If this interest you contact us and find more out today!